ABOUT US

We will continue to pursue development through science and technology

ABOUT US

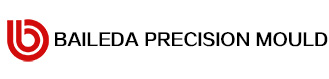

We will continue to pursue development through science and technologyPlastic injection mold is called as ‘basic of industrial’, and IT IS! With development of the CAD/CAE/CAM in software & hardware, it requests much more than steel cutting to make a good injection mold. That’s why we choose this industrial to make it success. To deliver a good quality injection mold to our customer worldwide is our task and strategy of the company. Not only good machining, but also (more important) easy using to produce high quality plastic parts. Meanwhile, to shorten development timeline of the mold itself will bring successful to our customer to save time and cost. Start from May 2011, we build the injection mold to our worldwide customers, especially for the component around the engine, like cylinder head cover, intake manifold, water pump, oil pam & filter, air filter etc. and becomes the leading of this industrial. |

QUALITY

QUALITY

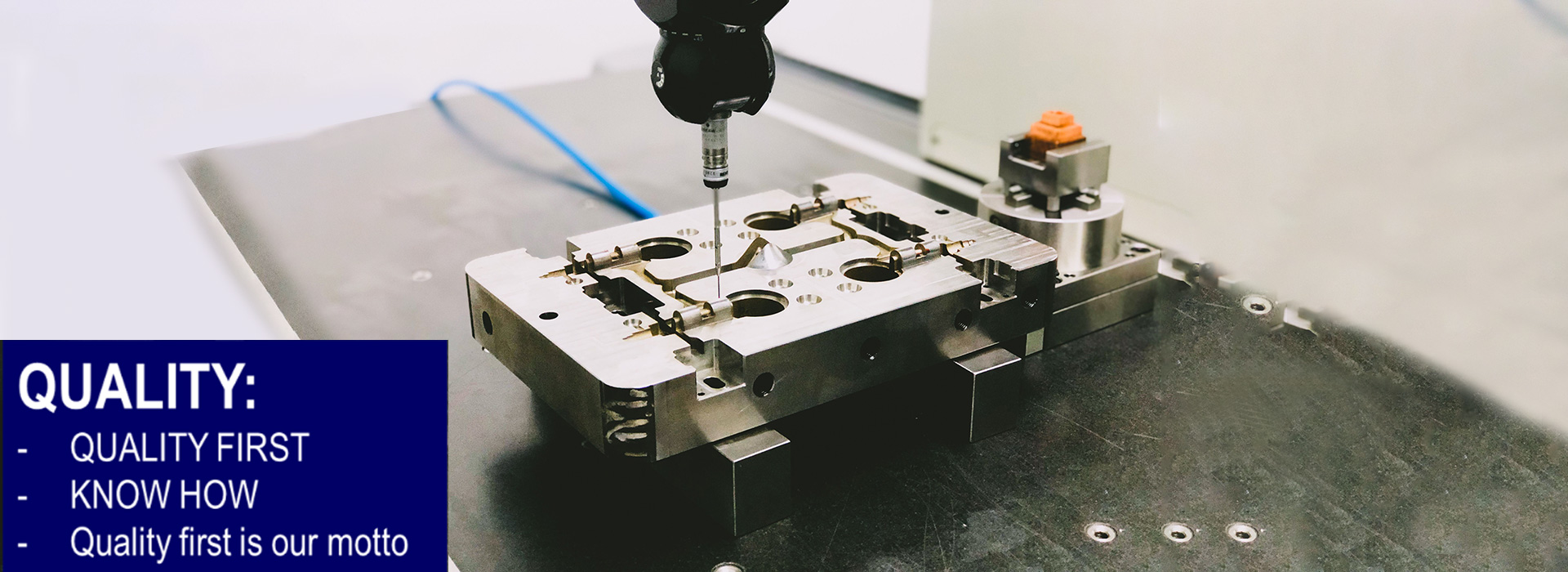

“Change is easy, improvement is far more difficult” - F.A. Porsche

We’re working to continue to improve our quality from engineering thinking, not only work with CMM everyday to check the quality.

What’s GOOD quality of mold? Because that’s the request from all customer & end user in each single tools.

Good quality means:

The mold itself = 3D design + tolerance.

The part itself fit to the drawing.

The process to produce the parts are easy.